This week I swapped cars with my parents so that I could perform their 60,000 mile service and you know that I was going to clean it up for them.

A Basic Detail to remove four years of use, hard water spots, and oxidation definitely made the Tornado Red paint look so much better. The interior was fully vacuumed, cleaned, and conditioned to make it look and feel as close to new as it’s been since 2017.

Since they utilize their hatch space a lot, I made sure their rear bumper received an OEM Bumperdillo (weird name, I know) to help protect against scuffs and scrapes.

I also finished the exterior with the newest formula of Opti-Coat Hyper-Seal, which is now rated to last one year.

Volkswagen Golf Alltrack - Opti-Coat Pro+

Finally…time for my own vehicle! My Alltrack was involved in a small collision back in January which resulted in the rear bumper and hatch being replaced. It was the end of February by the time the repair was completed and for me, the rule of thumb is to wait about 30 days after paint before coating. Well, those 30 days turned into almost three months and here we are.

After a decontamination wash, the rear bumper and hatch were polished to prep the surfaces for coating. I am so thankful to have had Josh at Croll’s Customs do the work and there wasn’t any major correcting that needed to happen. Now the back matches the rest of the car and I could finally put on the OEM bumper protection plate to make sure nothing dings up the bumper. Lastly, I coated the new tires with Optimum Tire Protection and Coating for six months of shine.

Mk7 Golf Sportwagen / Alltrack Towing Guide

Since owning my first 2017 Alltrack, I have seen a new towing capacity or general towing post weekly, sometimes almost daily, so I decided to put everything towing related in one post to make it easier to find.

No towing at all is RECOMMENDED for any Golf Variant (Sportwagen and Alltrack) in the United States (I imagine Canada might be similar since that falls under the North American Region). That is the official stance from Volkswagen. One common rumor that gets passed around is that if you tow, you will void your warranty. Your warranty won’t be voided if you tow, however, if you tow and let’s say your clutch goes bad because you decided to tow 3 tons of bricks, then it’s likely that repair will not be covered by your warranty.

Now, we all know that the same vehicles exist in the United Kingdom and Europe and over there they are rated for towing. It is important to note that since towing is common place over there, the vehicles are able to be equipped with an OEM trailer module which allows for improved stability and cooling when towing. Also, most tow with trailer brakes. Here is a breakdown of what their ratings are:

1.8T Sportwagen: 1,500 kg / 3,307 lbs braked (750 kg / 1,653 lbs un-braked)

1.4T Sportwagen: 1,500 kg / 3,307 lbs braked (670 kg / 1,477 lbs un-braked)

2.0 TDI Sportwagen: 1,600 kg / 3,527 lbs braked (710 kg / 1,565 lbs un-braked)

1.8T Alltrack: 1,500 kg / 3,307 lbs braked (750 kg / 1,653 lbs un-braked)

2.0 TDI Alltrack: 2,000 kg / 4,409 lbs braked (750 kg / 1,653 lbs un-braked)

It is important to remember that these numbers are for braked trailers and the hitches are not 1.25” hitches. Also these numbers are the same for manual and automatic (DSG) transmissions. Since most people I know that tow with their Golf Variants don’t have trailer brakes (myself included), here is a very safe rule of thumb: regardless if you use a 2” or a 1.25” hitch, do not exceed 91 kg / 200 lbs tongue weight and do not exceed 907 kg / 2,000 lbs total weight. That is the rating of Class 1 hitches (that is what is mostly available for our cars). Let’s move on to options for hitches.

Curt: 114223 Class 1, 1.25” - this part number includes the receiver and ball mount

Curt: 11422 Class 1, 1.25” - this part number is just the receiver, no ball mount

Draw-Tite: 24949 Class 1, 1.25”

EcoHitch: XV1VWGOLF02 Class 1 Hidden, 1.25” or 2”

Westfalia: 321782, 50mm ball and rated for 80 kg / 176 lb tongue and 2,000 kg / 4,409 lb towing

As for trailer wiring, there are two manufacturers with piggy-back options that I know of, and all work specifically on the NAR (North American Region) lighting behaviors of the brake and turn signals operating at the same time.

2015-2017 with halogen tail lamps: Curt C56391

2015-2017 with halogen tail lamps: Tekonsha 118730

2018+ with LED tail lamps: Curt C59236 - doesn’t appear to have plug and play adapter

2018+ with LED tail lamps: Tekonsha 118730

If you have European tail lamps or coded your NAR tail lamps to function as European, you’ll need to splice in Curt 56496 in order to have full trailer functions.

If you are interested in retrofitting an OEM trailer module to your vehicle, there is information here: http://bit.ly/mk7trailermodulediy

I really think that covers all the important aspects of towing with a Mk7 Golf Variant. I can update this post if new information arrives. Please be safe when towing, braking early and down shifting to use engine braking, and take care of your gear. To check on what your state requires when towing, visit this site for a break down: https://trailers.com/state-laws

Mk7 Golf Sportwagen/Alltrack Towing Module (J345) Retrofit

There are a lot of Mk7 Golf Variant owners that own a trailer of some sort and tow it frequently. I am one of these owners, having a fishing boat and a utility trailer, and like many, I had ordered a piggy back style harness to provide power to the trailer lights. Many people run harnesses like this on a plethora of vehicles but is it the best way to tow?

When I learned that Volkswagen offers a trailer module for almost every model in the European market, I wanted to learn more. What really sparked my interest was finding out that there is a retro fit kit available from US dealerships for the MQB Tiguan. I knew that many MQB chassis vehicles share a lot of components, to include electronics. I spent a lot of time cross referencing OEM wiring diagrams, part numbers, and cataloging the parts needed to make this happen and have successfully done this to my 2018 Alltrack S. First, let’s talk about why this is a better way to connect your tailer to your vehicle.

Lights (S, SE, SEL)

The most obvious part to this module is that it provides power to the trailer lights. There are three benefits to this module though: no piggy back harness, bulb status, and coding.

No piggy back harness means that the tail lamps stay plugged in directly to the body harness.

Bulb status is a neat feature that we may all be aware of with the vehicle as it is from the factory. If a bulb stops working on your vehicle, a warning is displayed on your information screen to tell you which one is out. Well this feature is now extended to your trailer. If your passenger turn signal on your tailer is not working, your vehicle’s information screen will tell you that it is out.

Coding is something that will effect anyone that has coded their tail lamps to operate as the European tail lamps do (brake and turn signal are independent from each other). When using the piggy back harness and this coding is performed, you need to run another wire and a converter to make the trailer work correctly. With the OEM module, any lighting coding done to the vehicle is carried over to the trailer without extra wiring.

ABS (S, SE, SEL)

This is the area that I cared most about. As soon as the trailer harness is plugged into the vehicle, the car recognizes that a trailer is now connected and that the vehicle should respond differently than if no trailer was present. The firmness of the brake pedal and the stability control are changed to reflect the trailer. If you have to make an emergency maneuver with the trailer on, the ABS (which controls many things on the vehicle) will make corrections for the fact that a trailer is attached. With the piggy back harness, the car just thinks that there is a lot of cargo in the car, which anyone that has had to make an emergency maneuver with a trailer knows that it is so much different than with no trailer. This is a pretty big safety feature.

Park Sensors (SE, SEL)

If your vehicle has the Driver Assistance Package and have park sensors on your bumpers, this feature will make you happy. Those sensors will sound off when you are approaching an object and obviously, the trailer stays close all the time. When plugged in, the module disables the rear sensors. You also get some extra features on the infotainment screen specific to the trailer that those without the package do not get.

Alarm (S, SE, SEL)

This is only available for vehicles with the advanced alarm installed and enabled. Most do not have this but if you do or choose to retro fit it, this will allow the vehicle alarm to sound if the trailer is disconnected and the car is locked. Great feature to scare away those trailer thieves.

Cooling (S, SE, SEL)

Another important feature is engine and transmission cooling. When towing, higher stress is placed on the powertrain and when the trailer is plugged in, the module tells the cooling system to run longer to prevent overheating. This applies to the engine fans, thermostat, and transmission.

There may be more features but these are the core ones that are the most important. I was originally going to make this a kit that I assembled but as you will see, it isn’t entirely plug and play and I decided to just make is a DIY instead.

Parts Needed

4F0-937-731 (Male connector for T6bc, B), $6.20 - 1 needed

A-018-545-47-26 [T6bc pin (large)], $2.64 - 2 needed

A-013-545-78-26 [T6bc pin (small)], $11.85 - 1 needed

6R0-972-930 (Male connector for T10p, C), $20.67 - 1 needed

N-907-647-01 (T10p pin), $1.04 - 3 needed

5NN-055-203 (Trailer hitch electrical kit), $230.39 - 1 needed

5G9-971-502-A (Retainer for module), $2.41 - 1 needed

1C0-973-119-B (Male connector for CAN), $7.08 - 1 needed

N-907-647-01 (Female pin for CAN), $1.04 - 3 needed

3D0-973-332 (Female connector for CAN), $17.17 - 1 needed

61-13-1-383-672 (Male pin for CAN), $1.65 - 3 needed

N-907-327-03 (Large pin for fuse panel), $1.34 - 2 needed

When dealing with wires, I tend to purchase the terminal pins and then crimp them onto the lengths of wires as needed. I do this because the finished product ends up looking much nicer and it is much cheaper to do. However, I recognize that not everyone has the tools that I do so I will give you an alternative to crimping terminal pins:

A-018-545-47-26 [T6bc pin (large)] is the pin that is on VW repair wire 000-979-152-E ($26.60). Since you need two pins, just order one wire and cut it in half.

A-013-545-78-26 [T6bc pin (small)] is the pin that is on VW repair wire 000-979-151-E ($25.20).

N-907-647-01 (T10p pin) is the pin that is on VW repair wire 000-979-009-E ($13.14).

N-907-647-01 (Female pin for CAN) is also the pin that is on VW repair wire 000-979-009-E ($13.14).

61-13-1-383-672 (Male pin for CAN) is the pin that is on VW repair wire 000-979-012-E ($18.02).

N-907-327-03 (Large pin for fuse panel) is the pin that is on VW repair wire 000-979-227-E ($25.20).

In addition to all of this, you will need spools of wire. You can use all one color or multi colored, which I use and recommend this: https://amzn.to/2LhqlYO

Looking at the schematic is important to understanding what is going on with the wiring. Since I do not have step by step photos of the process, this explanation will be the best way to understand what needs to be done. The trailer module has four connector banks, A, B, C, and D.

Bank A is a 24 pin connector that goes out to the trailer. Five of these pins are used for a traditional 4 pin trailer connector: pins 7 and 10 and jumped together, 15 is parking and brake, 18 is passenger turn signal, and 24 is driver turn signal.

Bank B is a 6 pin connector that is the main power connector for the module. Only three pins are used: pin 2 goes to ground, 3 goes to fuse panel location 38, and 4 goes to fuse panel location 28. Both are 15 amp fuses.

Bank C is a 10 pin connector that connects the module to the vehicle’s CAN gateway, or vehicle network. Only three pins are used and all three go to the BCM behind the driver side of the dash. The BCM has two large connectors that are needed for this, the one labeled A and the other is C. Pin 2 is the only one that goes to the C connector and that is for the brake switch signal. Pin 3 goes to location 16 of the A connector and 4 goes to location 17 of the A connector. Now what took me a little figure out is you have two options here. One is to just splice the new wire into the factory wires that go into those positions. I don’t like messing with factory wires so I went with the way that is shown. The three brand new wires that you are running from the hatch (where the module is located) will have two ends. Three of these end will have a male pin and three will have a female pin. The three male ends will go into the small 3 pin female connector that you purchase (3D0-973-332). The three female ends replace the factory wires in the BCM connectors. The three female factory wires then are plugged into the small 3 pin male connector that you purchase (1C0-973-119-B). All of this allows for one nice CAN Gateway loop without cutting or splicing the factory wires once the two small 3 pin connectors are plugged into each other.

Bank D is left empty at this time. This is used specifically for the OEM European swiveling hitch and the switch that goes with it. I have these pins written out but if you are looking to wire this up specifically, not only can I order you those parts, just contact me and I can provide you the wiring as well.

Personally I feel that everything else is pretty easy to figure out. The module and its retainer bracket is connected under the tray where the OEM tool kit is located on the driver side of the hatch. I believe it is one bolt that holds that tray in place and then the retainer is snapped into that tray and the module snaps into the retainer. You will need to lift the hatch carpet in order to route the trailer wires. You remove one of the round rubber grommets and the nice part is the OEM module kit wiring has a grommet built in to replace the blank one. Now, you will need to loosen up the tape on the built in grommet to be able to shift the position. The kit is designed for a Tiguan and it is close, but not close enough.

The wires that go to the front of the vehicle get snaked up through the driver side channel with the rest of the wiring. If you don’t have a nice snake tool to run the wires, you can grab THIS ONE from Amazon. You will need to take out the dash cubby and the trim pieces around the hood latch lever in order to get to the BCM. The BCM plugs are probably the hardest part of the job, next to plugging the fuse panel wires into the back of the fuse panel. I really don’t have many suggestions to making it easier but take your time. The fuse panel wires do just push into the back of the panel so make sure they are going into the correct positions. Another way you could add the fuses to the panel can be found in “A way to add fused circuits to your fuse panel” on VWVortex.

You will have to figure out your own method for mounting the trailer wiring. I had some flat aluminum and threaded rivets that I fabricated onto the bumper.

Coding

For this, I used VCDS to do my coding but I am sure you can use any other program to do this. Also, I only have coding for my vehicle, which is an S model with no packages. There may be additional coding for the park sensors.

Select: 19 - CAN Gateway

Select: Installation List

Scroll and check the box for: 69 - Trailer

Select: Save coding

Close Controller, Go Back - 06

Select: 03 - ABS Brakes

Select: Adaptation - 10

In the first drop down menu, select: Vehicle and trailer stabilization

Change the value to Activated and select Do It!

Select: Go Back

Close Controller, Go Back - 06

Select: 01 - Engine

Select: Coding - 07

Toggle to Byte 5 and make sure Bit 4 is checked

Do It!

Close Controller, Go Back - 06

Now, I will share with you all of the coding Bytes/Bits I have on my module:

Select: 69 - Trailer

Select: Coding - 07

Byte 0, Bit 0-7: 02 Market/Country: North American Region (NAR)

Byte 1, Bit 4-7: 10 Partial Network Operation active

Byte 3, Bit 0-7: 00 Terminal 30 Output (Pin 9) NOT active)

Byte 4, Bit 0-7: 02 Terminal 30 Output switched (Pin 10) active while Trailer connected

Select: 09 - Cent. Elect.

Select: Security Access - 16

Enter: 31347

Select: Adaptation - 10

Search for Networking-Anhaengeranschlussgeraet

Change the value to Installed

Do It!

And that is it! I think. I know it isn’t an absolute complete guide to the job but it isn’t a job for the faint at heart either with or without guidance. Feel free to comment on here or email me about this if you have any other comments or questions about this.

Bearded Elevation System

This post has been a long time coming and I am so happy to be typing this out and I am not even close to being done!

Since buying our Alltrack back in July, I have seen many inquiries about lift kits. Almost every day I was seeing a new post about it. I originally reached out to a company that does lifts for Subarus and I had also done a poll on two different Facebook groups to see what the legitimate interest would be if a kit were to be produced. After the company took a long time to respond, I decided to undertake the task myself. There was a huge learning curve for me since I had not used AutoCAD since high school (almost 15 years ago), nor did I have access to any of the resources needed to 3D print or produce a prototype.

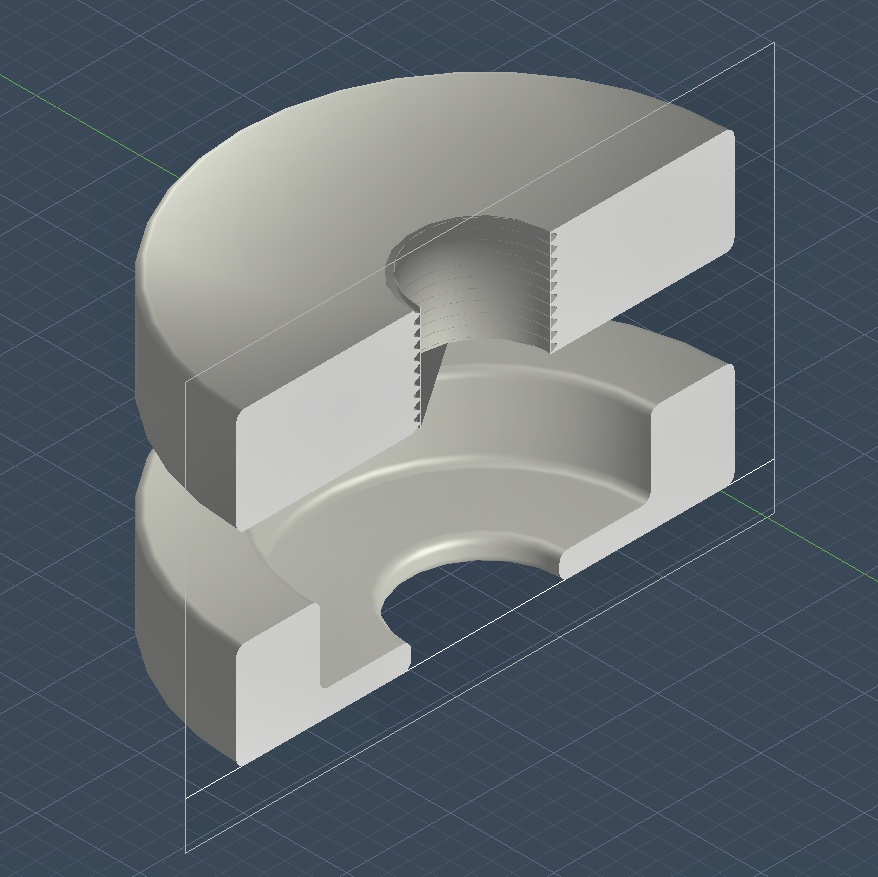

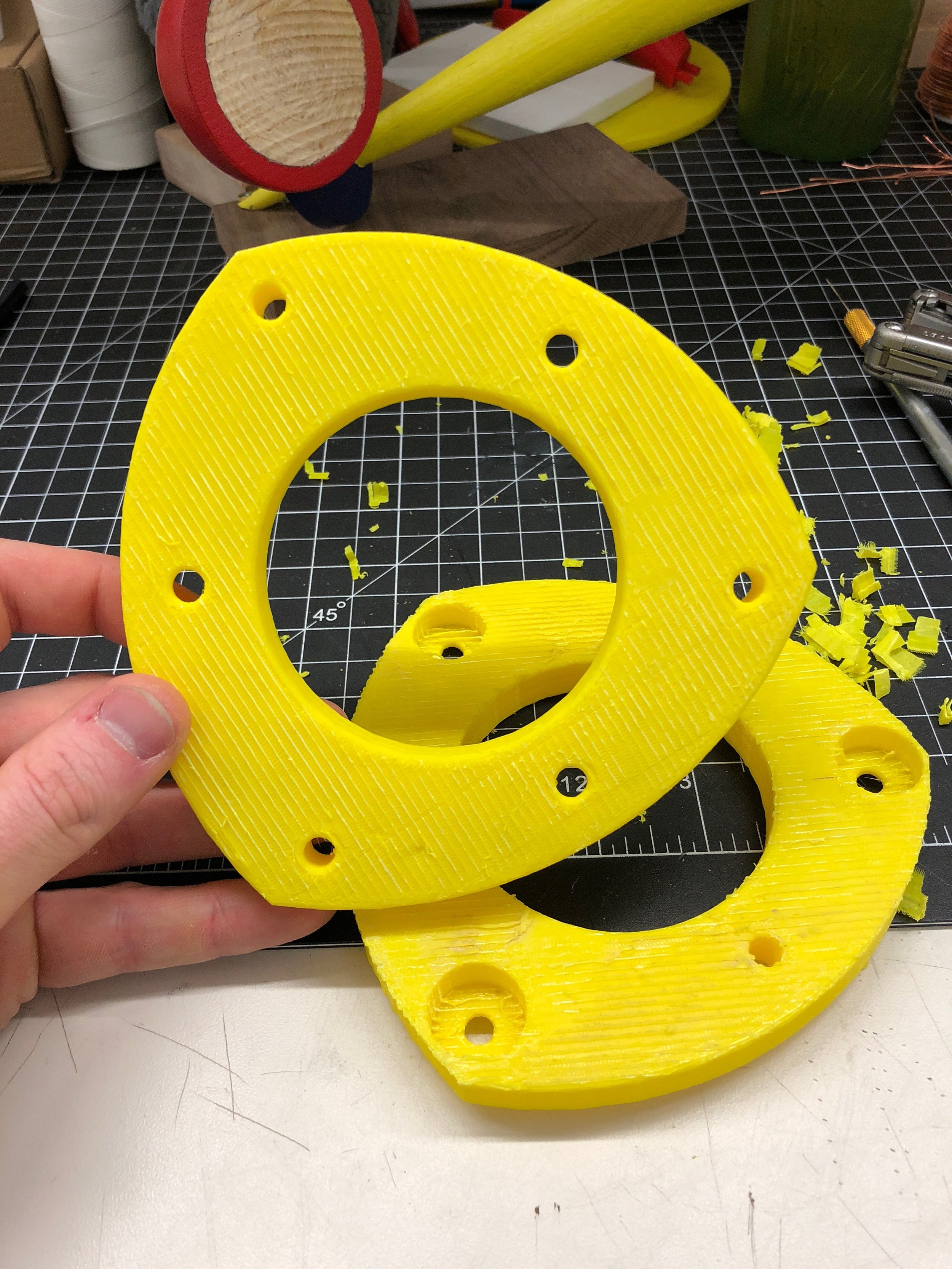

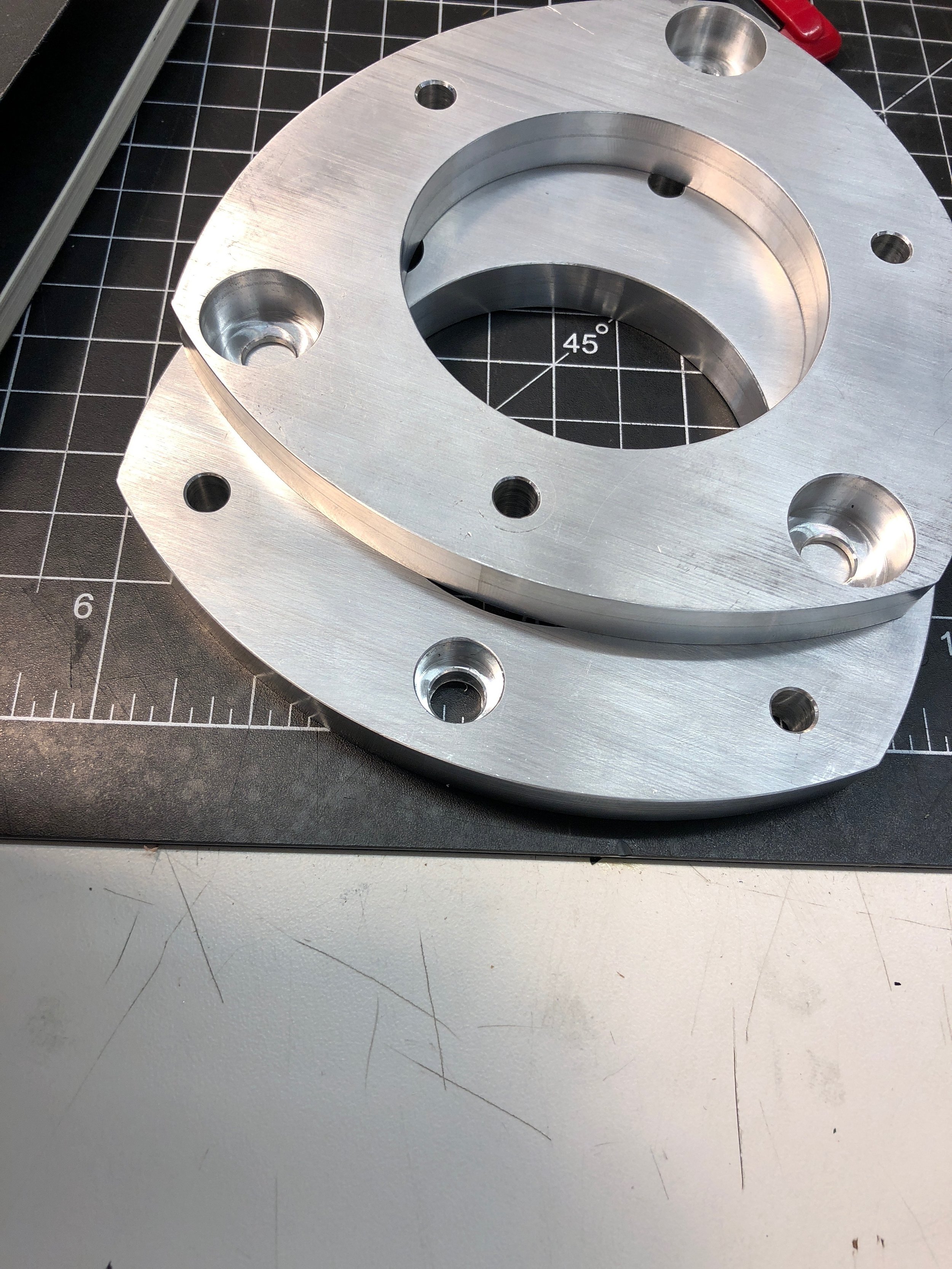

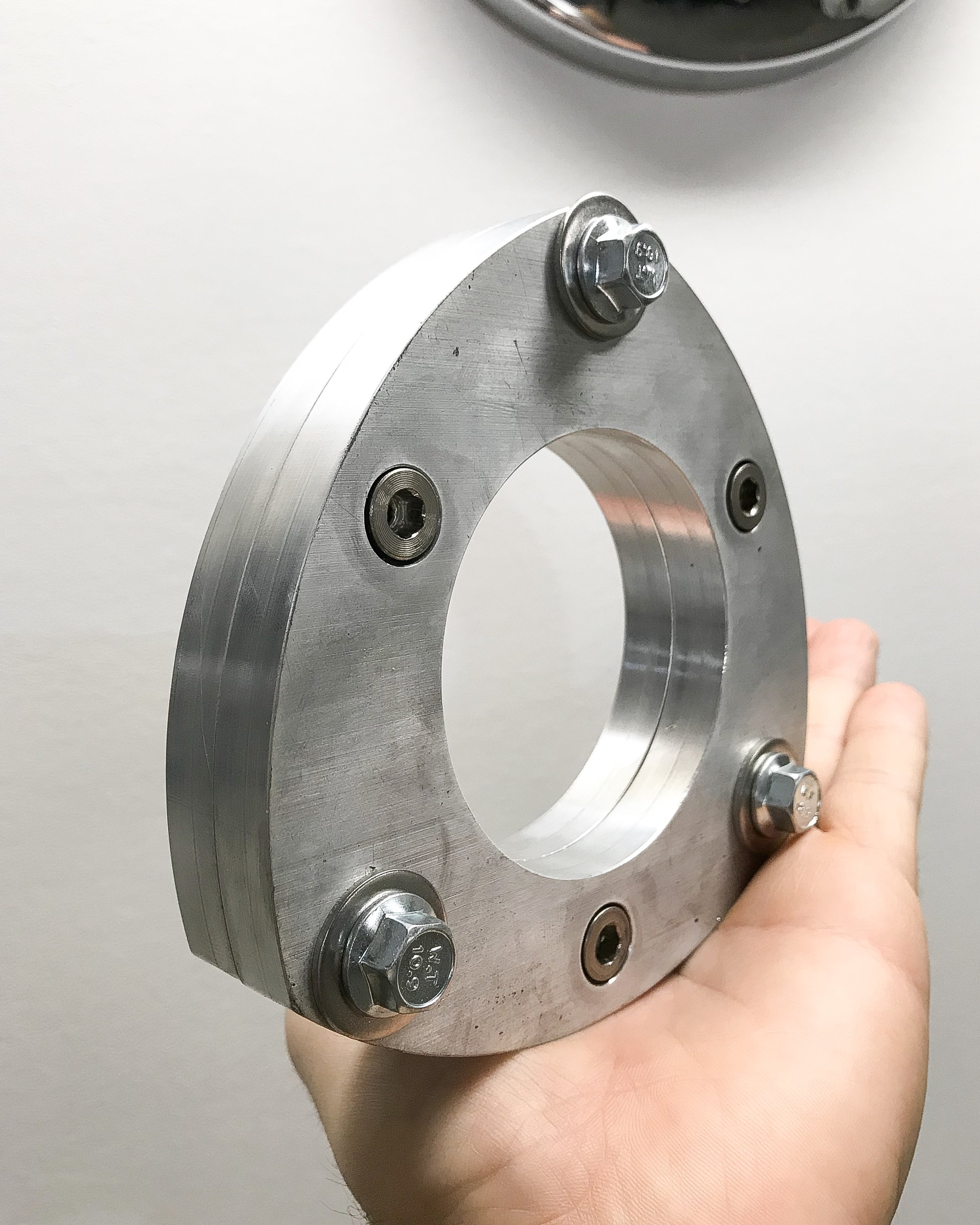

I will fast forward through all of the trial and error bits but I did finally settle on a design that I thought was unique enough that I wanted to protect my intellectual property. I filed for a provisional patent for my front lift kit spacer and before I go further, I guess I should explain why.

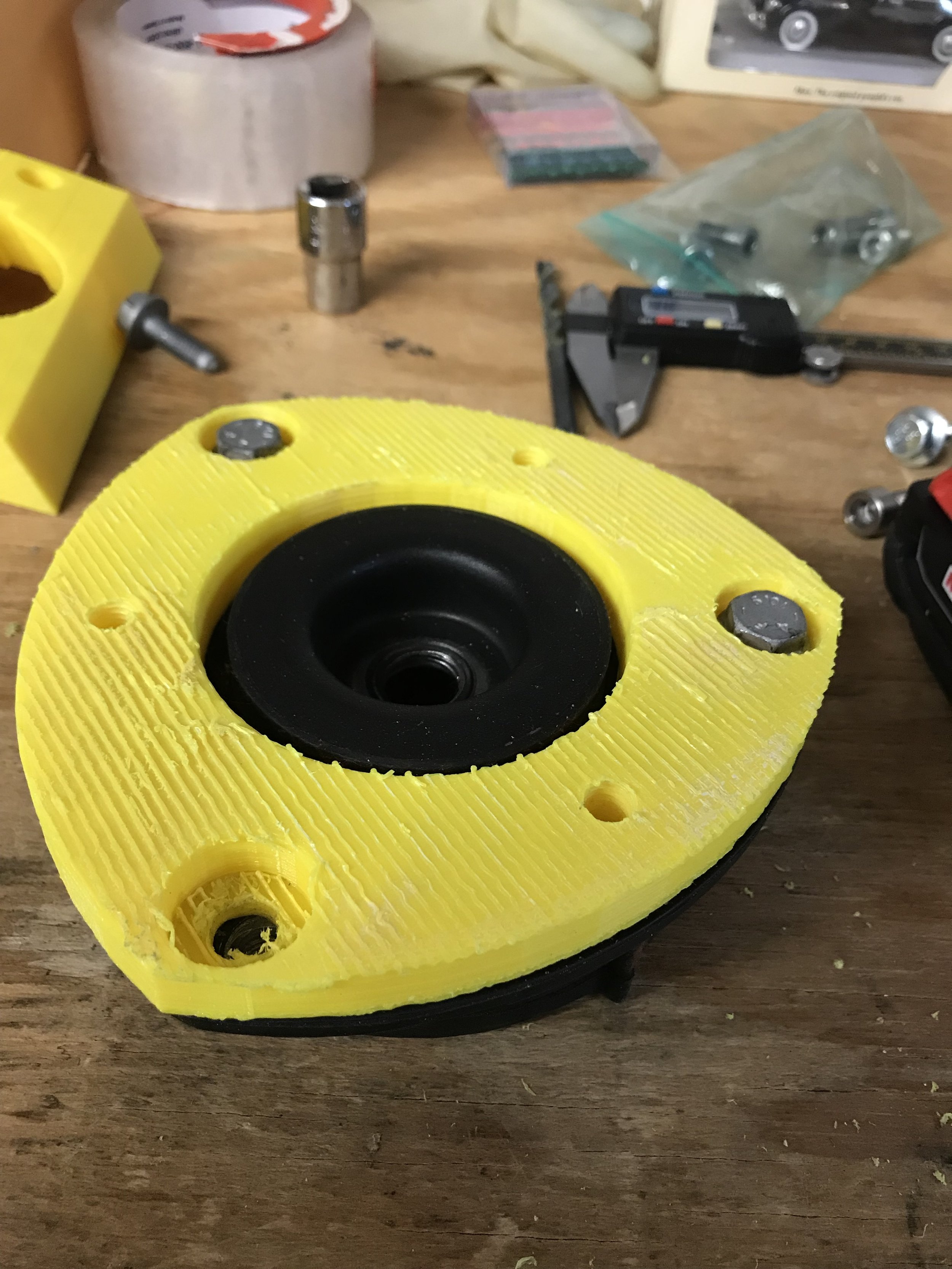

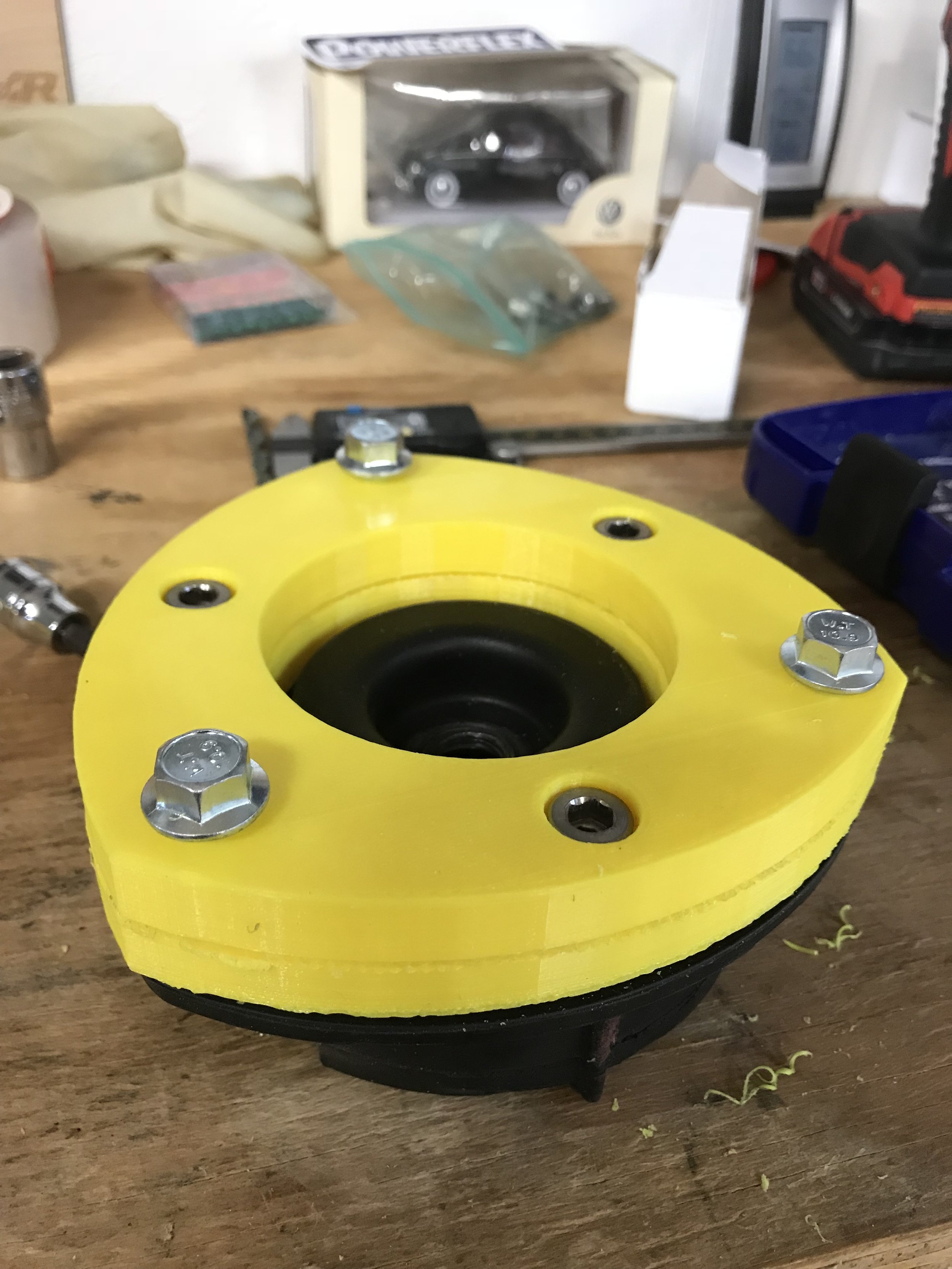

The Mk7 Golf is on Volkswagen's MQB platform and like other platforms in the past, it has a MacPherson front strut and a multilink independent rear shock and spring. The concept of lifting a car with this setup is simple: a spacer in between the front strut assembly and the body and the rear spring and the body. The front has a rubber strut mount that is bolted to the body and my concern was, and still is, using a single piece spacer with longer bolts to achieve the lift. This is where my idea for a two piece spacer came into play and that is what I filed a patent for. This will use OEM strength and length bolts and therefore not be more prone to failure from torque.

Recently, I got the lift kit on the car and I first installed a 1/2" lift and then a 1" lift. These will be the two sizes that I will be offering through The Bearded Detailer so I wanted to be sure to install both.

After a week of driving on the kit, I went ahead and ordered the all terrain tires I decided on and dropped off the 16" steel wheels I acquired for powder coating.

I decided on the Nokian Rotiiva AT in a 215/65R16. The reviews were really good and they have a pretty good wear rating. I won't lie to myself or anyone about the amount of highway driving I do and that won't change with this setup so I needed to be able to have a tire that could hold up to that. The steel wheels got finished in a metallic silver very close to the OEM silver alloys and their specs are 16" x 6.5", et50. I also picked up OEM wheel caps (5N0-601-169-X-RW) that I believe reference to a Canadian Tiguan setup. I could be wrong on that but I have had them before and if I am going to run steel wheels, that is the only way for me to go.

Installation day finally came and before the tires were mounted, I coated the wheels with Opti-Coat Pro to make sure they stay as clean as possible when I do end up off road. The dealership was able to balance them with stick on weights since their finish was now similar to alloys. I stuck around and had my friend Connor align the car since the alignment hadn't been touched since the lift kit was installed. I will have more information on the alignment when the kit is finally available to the public but I am content with the specs.

I drove out to get photos that evening and I am so happy with how it all has come together. I will be spacing out the rear wheels 15mm as well. I am content with where the front wheels sit.

Also took the car to a small local show on a whim and the car and kit got some interest. Overall, the car now sits about 1.5" taller than a stock Alltrack and while the tires aren't meant for performance cornering, I am happy with the ride of the car. I do recommend an upgraded rear sway bar and some form of engine tune for a few more ponies due to the added unsprung weight.

Behind The Scenes!

First and foremost: I want to thank everyone that has shared and supported the release of the kit. This can only be a success if more people know about it.

I will get to the alignment. I can't force anyone to get an alignment but do yourself and your tires a favor and get an alignment. You should be doing an alignment once a year at minimum as it is.

So this is a printout of my alignment and I will state that the BEFORE is not before the lift kit. That is with the lift kit as I drove it to the dealership and the AFTER is how I drove it home and how it currently sits. I never had the car aligned prior to the lift kit but based on printouts of others with stock Alltracks, I can say that the 1" kit added about .4º camber in the front and .13º in the rear. The factory specs call for -.27º ± .50º camber in the front and -1.33º ± .50º camber in the rear.

The front is what should be focused on since it isn't adjustable and the rear is. He was able to get the caster and toe as close to factory as possible and then he adjusted the rear camber about a half a degree to match the front movement. I think my next alignment, I will make the rear match the front closer.

My overall thoughts on the performance of the car? I love it. One thing you have to remember is that the center of gravity has been raised 1" so the will be a slight difference in cornering. This is also true of tires with larger sidewalls. But after a few days of driving, you will get used to the feeling and realize that it is not unsafe. I do about 18,000 miles of driving a year and many family trips with my kids and dog. The last thing I want is an accident with them in the vehicle with me.

Over the Memorial Day weekend, we took a trip up to my parents' house in Bradford County (about 300 miles round trip) and made sure to hit some rural routes that I grew up driving on and leaving the beaten path. The car performed exactly the way I wanted it to.

And that about wraps this up for now. The group buy is still active on Facebook and on the Swag Store until the 21st of June. Again, I thank you all for the support and I look forward to getting these out into the hands of many Alltrack owners!